This enables offshore energy operators to make timely, informed decisions regarding asset integrity. Specific examples include providing critical measurements to help clients avoid unscheduled interruption of production and enabling reverse engineering of damaged subsea equipment to enable repairs in-place. During several recent offshore deployments, Kraken’s SeaVision technology has shown clients that as-built 3D dimensions of installed subsea structures differ from their existing documentation, especially when servicing aging assets.

Kraken’s SeaVision business unit continues to make progress across a variety of fronts including:

- In 2022, Kraken acquired over 10 terabytes of subsea data for offshore oil and gas and renewable energy customers across several countries including Brazil, Canada, Denmark, Estonia, Germany, Nigeria, Norway, and Poland. Applications included anode volumetric measurements for offshore wind farms, mooring chain inspection for offshore oil and gas infrastructure, and subsea metrology services. In 2022, SeaVision services have delivered over one hundred (>100) 3D models and metrology for offshore wind and oil & gas clients. Kraken’s SeaVision technology is expected to become part of several clients’ yearly asset integrity campaign.

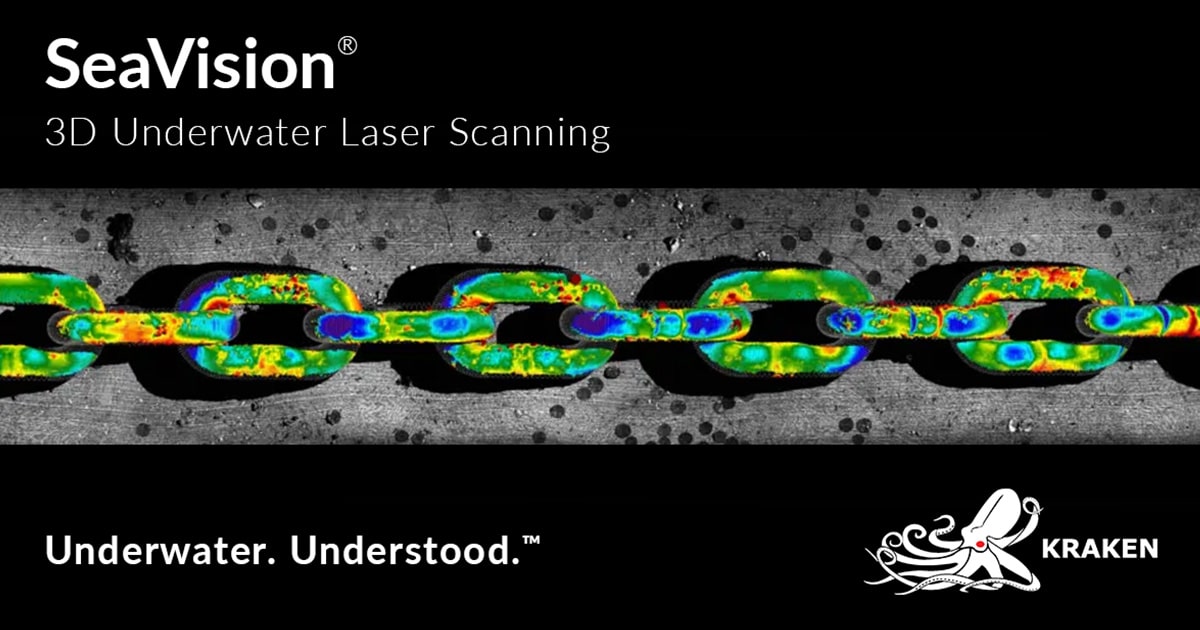

- Kraken is continuing the commercialization of a unique, non-contact SeaVision® Mooring Chain Inspection Tool (MCIT). This tool can be used to support existing offshore oil and gas inspection requirements, as well as upcoming offshore wind inspection requirements by providing millimetric accuracy 3D digital twins of critical subsea infrastructure. The SeaVision MCIT will also significantly reduce the cost of mooring chain inspections, as Kraken has also developed extensive data analytics capabilities to process mooring chain data efficiently into corrosion and dimensional measurements requirements for mooring integrity analysis.

- In 2023, Kraken’s SeaVision technology will be certified for DNV class inspections as well as accreditation of performance as per ISO standards. Delivering an accredited measurement according to international standards is important to clients that rely on SeaVision measurements to make critical decisions regarding asset integrity, life extension, and repairs.

- In 2022, Kraken developed automated calibration, measurement, and report generation tools as well as a real-time workflow based on deep learning which enables automatic structural tracking and measurement of mooring chains. These tools have reduced the turn-around of models and measurements by a factor of ten times.

- Customer satisfaction continues to be a high priority for all Kraken service deliveries, including the SeaVision team. Commenting on Kraken’s SeaVision laser scanning services, the Client Rep for an major international energy company said, “We received outstanding service and support from Kraken throughout our engagement, with pre-engineering and offshore services delivered. Kraken delivered a highly innovative solution, in a challenging time frame whilst delivering excellent customer support throughout our project.”